Pixy2 Quick Links

Basics

Connecting Pixy2 to…

Pixy2 Modes / Programs

Software and Support

Basics

Connecting Pixy2 to…

Pixy2 Modes / Programs

Software and Support

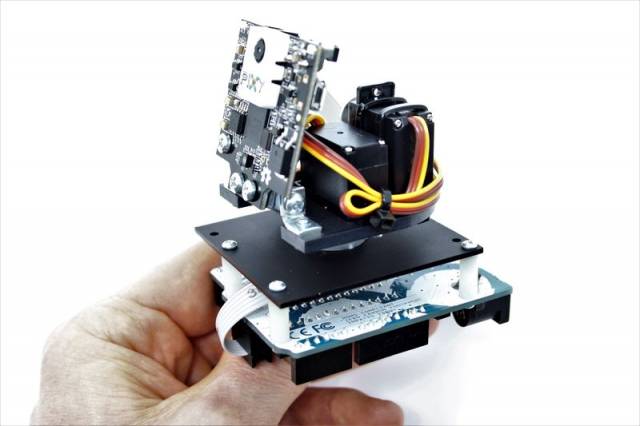

When combined with Pixy, the pan/tilt mechanism makes a fun demo — a good “hello world” for Pixy (no Arduino required). The pan/tilt mechanism comes in a kit and requires some assembly.

You will need the following (in addition to a Pixy2 and a pan/tilt kit):

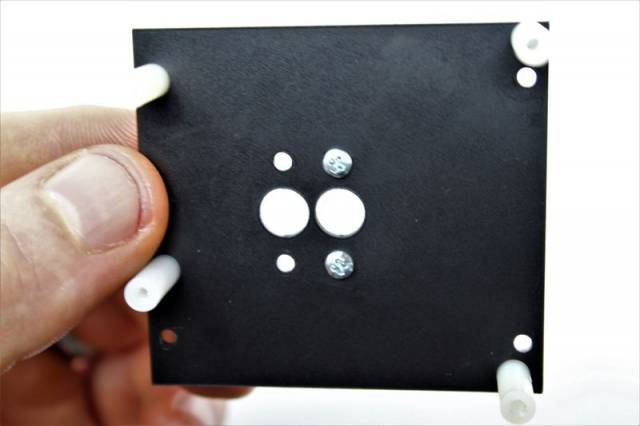

There are lots of different types of fasteners included in this kit. Refer to the picture below to help you find which fastener we are referring to in the instructions below.

1 - Find the “cross” servo horn in the servo baggie. And use the wire cutters to clip three of the legs as shown. Put the modified horn aside, or put it on one of the servos for safe keeping.

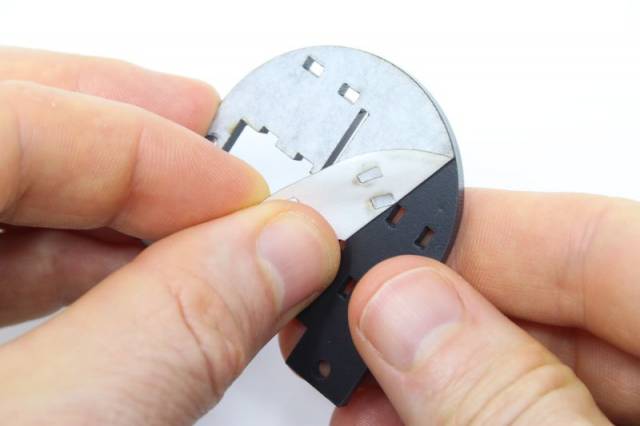

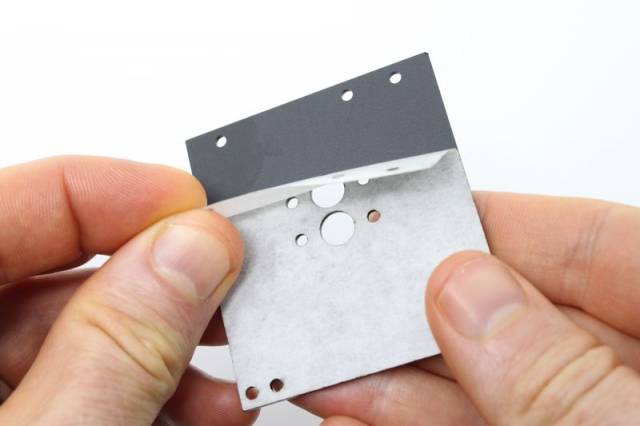

2 - Remove the paper backing from the “frame” plastic piece as shown.

3 - Remove one of the servos from its bag and attach to the frame by inserting its side-flange into the frame slot as shown. The flange of the servo fits very snug in the slot and requires some force. This will be the tilt servo.

4 - Flip the frame and servo over and attach a cable-tie as shown.

5 - Attach a second cable tie and tighten by hand as shown.

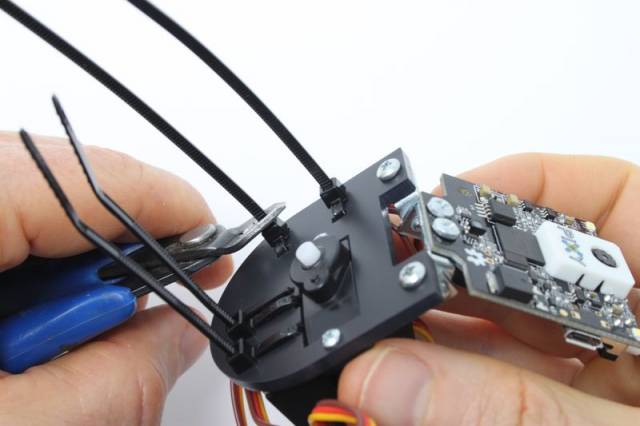

6 - Use pliers to tighten the cable ties by grabbing the ends of the cable-ties and pulling.

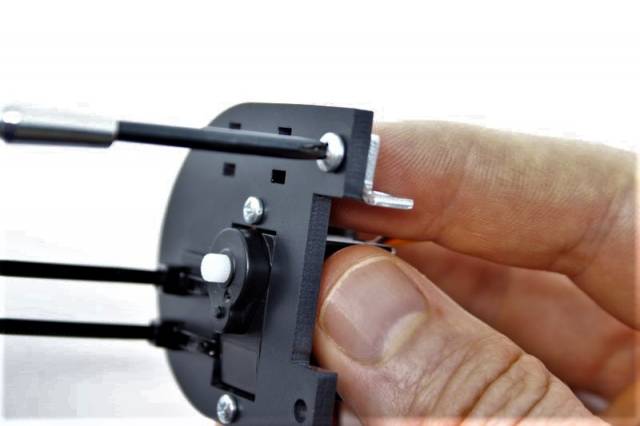

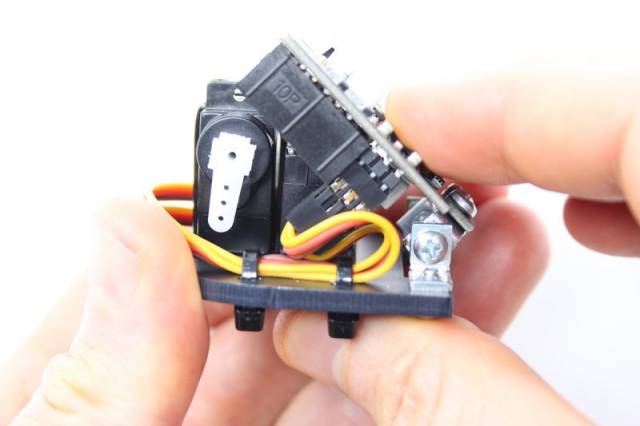

7 - Remove the second servo from its bag and fit it into the hole in the frame as shown. This will be the pan servo.

8 - Attach the servo to the frame by using two long tapping fasteners, being careful not to over-tighten, which might strip the plastic.

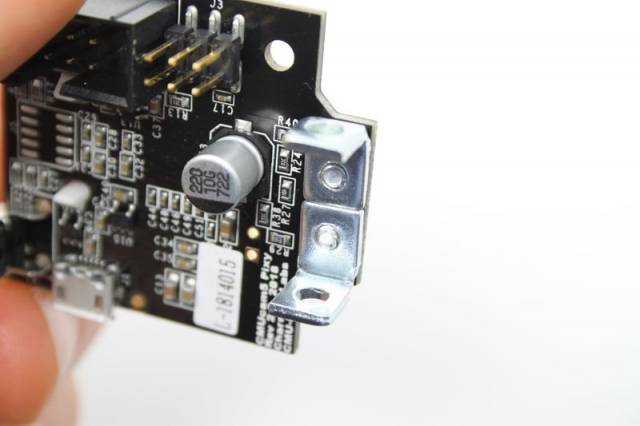

9 - Take all five metal right-angle brackets out and examine them. Notice that three of them have two threaded holes and two of them have one threaded hole. We'll call these two-threaded and one-threaded brackets, respectively. Go ahead and separate these two bracket types into two piles to make things easier.

Grab a two-threaded bracket. If you look really closely, you'll notice that one of its legs is ever-so-slightly longer than the other. Say what? It's true— I don't know why. But you can best see this by looking at the holes in the bracket. One of the holes in centered in its leg and the other hole is not centered, because its leg is slightly longer. It's enough of a difference to cause issues if not taken into account.

Using a long 4-40 fastener, attach a two-threaded bracket to the frame as shown. The longer leg of the bracket receives the fastener (and the shorter side sticks up). Do this on the other side of the frame with another long 4-40 fastener and two-threaded bracket.

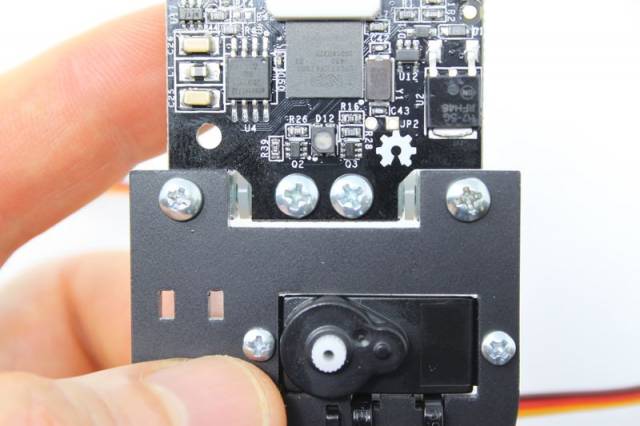

10 - Attach a one-threaded bracket to the bottom of Pixy with a short 4-40 fastener as shown. (The threaded leg receives the fastener and the non-threaded leg sticks up.) Do this on the adjacent hole of Pixy with another short 4-40 fastener and one-threaded bracket.

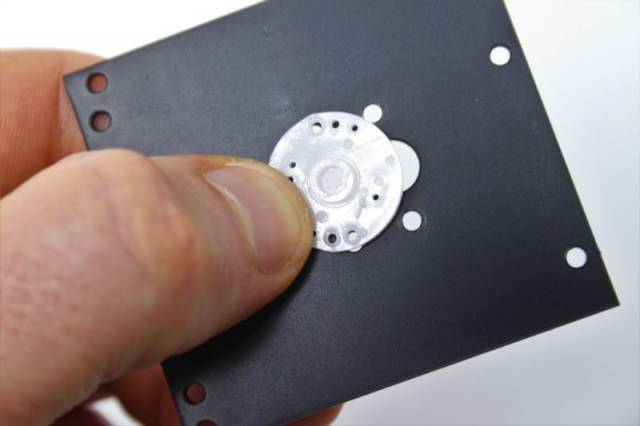

11 - Take two nylon bushings and press them into the non-threaded holes in these brackets as shown.

12 - Insert Pixy between the brackets on the frame as shown. Use two long 4-40 fasteners to attach Pixy to the frame assembly, one on each side. Note, these fasteners are used in a unique way – they don't “fasten” Pixy, but “capture” Pixy between the brackets and form the axle that Pixy will use for tilting. It may be necessary to loosen the fasteners that attach the brackets to the frame to get these fasteners to screw in all the way

13 - Bend Pixy's tilt axis all the way down as shown. Scrutinize things to make sure everything is square. If things aren't square (if pixy is crooked, etc), loosen the fasteners that attach the brackets to Pixy and/or the frame and adjust until things are nicely square, then re-tighten.

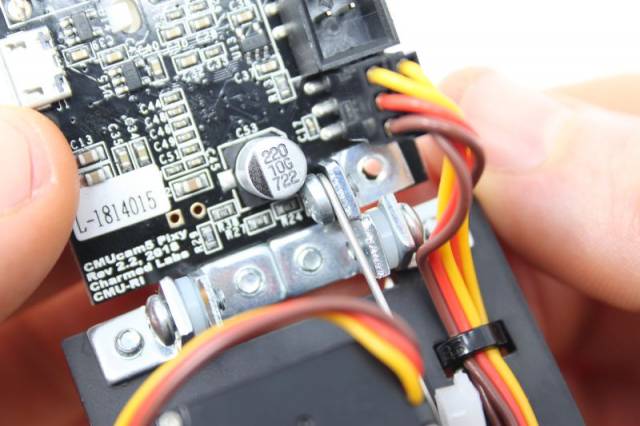

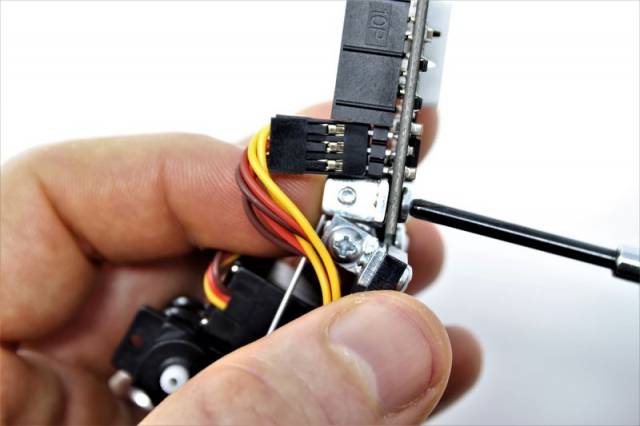

14 - Plug the servo wires into Pixy's servo connector. Looking at the back of Pixy2, the pan servo goes on the left-side of the connector; the tilt servo goes on the right-side of the connector. (Which is the tilt axis? It's the one that's held down by the cable ties.)

15 - Use cable ties to hold down the cables as shown.

16 - Make sure there is enough cable slack for Pixy to tilt fully before bringing the cable ties snug. Do not overtighten the cable ties, or it may damage the wires.

17 - Use the wire cutters to remove the ends of the cable ties as shown.

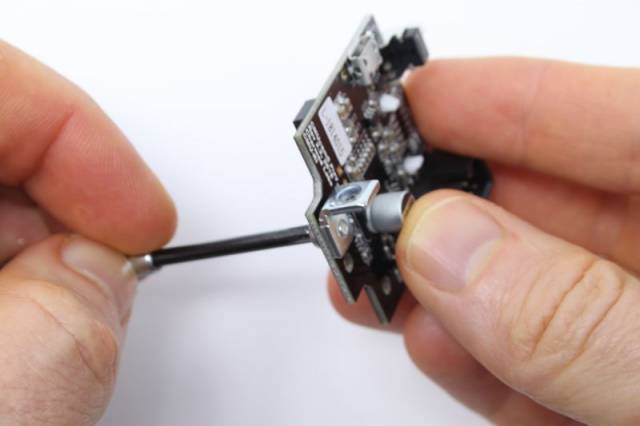

18 - Grab a short 4-40 fastener, the wire pushrod, and the remaining 2-threaded bracket. Attach the pushrod to the bracket as shown with the longer leg of the bracket receiving the fastener. Also, note the orientation of the pushrod in the picture to make sure it isn't “flipped”.

Lastly, do not tighten the fastener on the pushrod. Leave the fastener loose, such that the pushrod is free to rotate around the fastener shaft. It will remain this way so the tilt axis can move freely via its pushrod.

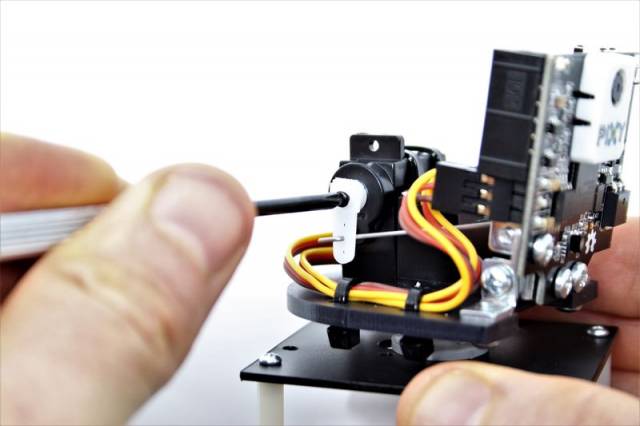

19 - Thread the other end of the pushrod into the modified servo horn as shown. The servo horn should have 3 pushrod holes – the middle hole is recommended.

20 - Line up the pushrod and its bracket on Pixy as shown.

21 - Use a short 4-40 fastener to attach the fastener to Pixy as shown.

22 - Plug a USB cable into Pixy to let Pixy power-up and “zero” the servos.

23 - Leave the USB cable plugged-in and attach the tilt servo horn to the tilt servo. The servo horn and Pixy should be close to upright as shown.

24 - Peel the backing off of the pan-tilt base.

25 - Use a round servo horn and line it up on either of the two possible positions on the pan-tilt base. You may prefer to mount the servo-horn centered if you are just using the pan-tilt mechanism on a desktop (for example), or you may prefer to mount the servo-horn off-center if you plan on mounting the pan-tilt mechanism on a robot. The off-center position allows Pixy2 to look over the edge of the base more effectively.

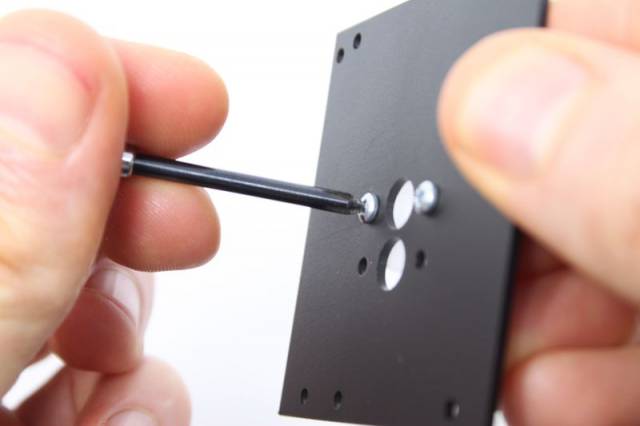

26 - Use the short tapping fastener to mount the round servo horn to the pan-tilt base as shown. The long tapping fastener will prevent the pan servo from rotating, so be sure to use the short fastener.

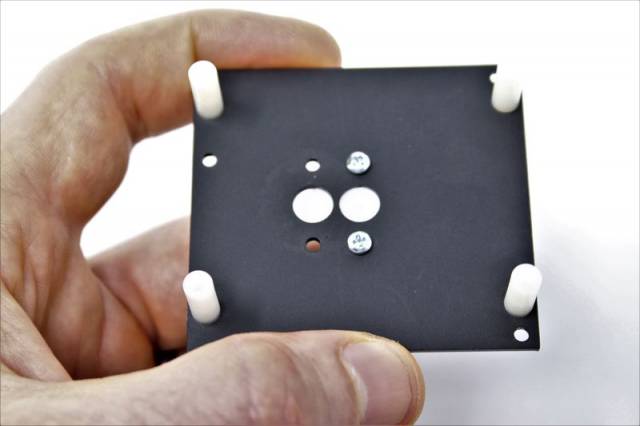

27 - Use the four nylon stand-offs and four 2-56 fasteners to attach the stand-offs to the pan-tilt base as shown.

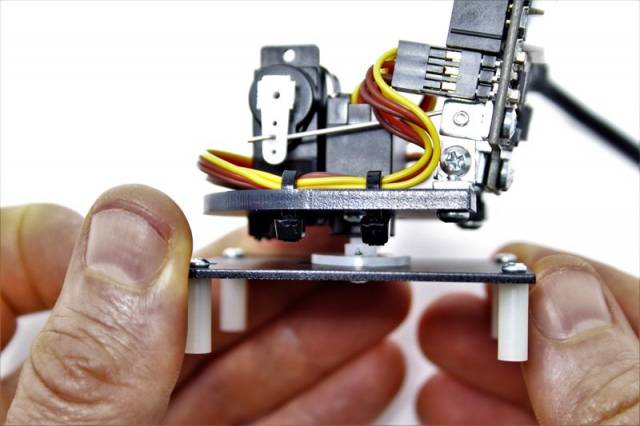

28 - Attach the base to the pan servo as shown.

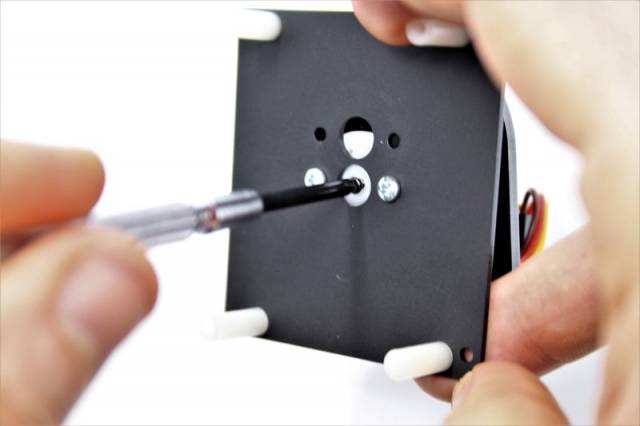

29 - Use the servo horn fasteners (found in the servo baggies) to attach the tilt and pan servo horns.

30 - The base plate has two hole patterns for attaching the standoffs: a rectangular hole pattern that we showed above and an Arduino hole pattern if you want to mount your Pixy pan-tilt on top of an Arduino. If you wish to mount your Pixy pan-tilt on top of an Arduino, see below.

And here is another configuration with the Arduino and base plate flipped.

You're done!

What's next? Run the pan-tilt demo.